Uvod: temelj savršene majjace Skromna majica kratkih rukava dio je globalne garderobe, ali nisu sve majice jednake. Duboka razlika između prosječne košulje i one koja djeluje kao druga koža leži...

Pročitajte višeobičaj Tekuća tkanina za amonijak Pique Mesh

Tkanina za tekuću amonijačnu krušku prihvaća jedinstvenu tehnologiju liječenja tekućeg amonijaka. Kroz prodiranje i oblikovanje tekućeg amonijaka na vlaknima u okruženju s niskim temperaturama, tkanina je glađa i osjetljivija na dodir, a istovremeno održava izvornu mekoću. Tretman s tekućim amonijakom također daje tkanini dobru elastičnost, osiguravajući da odjeća čvrsto uklopi u zavoje tijela i pokaže dobru figuru bilo u svakodnevnom trošenju ili tijekom vježbanja. Dizajn kruške mreže još je jedan vrhunac ove tkanine. Jedinstvena mrežasta struktura ne samo da uvelike pojačava prozračnost tkanine, omogućavajući znoj da brzo ispari i održava tijelo suhim i ugodnim, već također daje tkanini jedinstven vizualni efekt, predstavljajući trodimenzionalni smisao i slojevito, što odjeću čini jednostavnom i modernom. Tkanina od kruške od tekućih amonijaka također ima dobru apsorpciju i znojenje vlage. U vrućem ljetu može učinkovito apsorbirati i ispuštati znoj s površine kože, izbjegavajući ljepljivost i omogućiti ljudima da uživaju u hladnoći uz održavanje urednog i sposobnog izgleda.

-

-

Kao tekstilno inženjerstvo i odjeća pružatelja rješenja, naša je tvrtka specijalizirana za pronalaženje, procjenu i opskrbu naprednih tkanina za proizvođače odjeće, robne marke i B2B timove za naba...

Pročitajte više -

1. Zašto je mješavina svilenog pamuka pametan izbor za vrhunske košulje po narudžbi? Potraga za savršenom tkaninom za košulju često dovodi do klasične dileme: luksuzni osjećaj svile nasuprot pra...

Pročitajte više -

Istraživanje prednosti Jacquard merceriziranog pletiva za osjetljivu kožu Osobe s osjetljivom kožom često se bore s pronalaženjem tekstila koji pruža udobnost bez iritacije, a to je mjesto gdje ...

Pročitajte više -

Otpakiranje superiornosti Supima pamučnog vlakna Prednost iznimno dugih spajalica: izdržljivost i mekoća Temelj ovog iznimnog tekstila leži u korištenju Supima pamuka, sorte poznate po s...

Pročitajte više

How does Liquid Ammonia Pique Mesh Fabric improve the overall performance of sportswear?

In the field of sportswear, the choice of fabric is directly related to the athlete's comfort and performance. As a new fabric, Liquid Ammonia Pique Mesh Fabric has become an ideal choice for high-performance sportswear for its excellent breathability, comfort and durability. This fabric enhances the overall performance of the fabric through liquid ammonia treatment technology, which not only improves the athlete's sports experience, but also meets the dual demands of functionality and comfort in the market.

First, the Liquid Ammonia Pique Mesh Fabric significantly improves the breathability of sportswear. Traditional sportswear fabrics sometimes cause the wearer to feel stuffy and uncomfortable due to inadequate sweat absorption, which affects his or her sports performance. The liquid ammonia treatment optimizes the fiber structure, so that the fabric can better absorb moisture and sweat and keep the skin dry. Especially during high-intensity exercise, liquid ammonia mesh cloth can effectively discharge sweat from the body surface, evaporate quickly, and keep air circulation, thereby reducing discomfort caused by moisture. This efficient breathability is a crucial feature in sports equipment, and it helps athletes stay in their best shape during long training and competitions.

Secondly, liquid ammonia treatment can also enhance the durability of the fabric. Sportswear requires long wear, frequent washing and intense exercise loads, so the durability of the fabric is crucial. Liquid Ammonia Pique Mesh Fabric uses special treatment to make the fabric's fibers tighter and stronger, thereby enhancing its resistance to tensile and wear. Whether during intense exercise or after multiple cleanings, the liquid ammonia mesh cloth can still maintain good shape and performance, extending the service life of sports equipment. This durability makes liquid ammonia mesh an ideal choice for sportswear manufacturers, especially for sportswear that need to withstand high intensity use.

Another major advantage of liquid ammonia mesh cloth is its comfort. The comfort of sportswear depends not only on the softness of the fabric, but also closely related to the breathability, moisture absorption and elasticity of the fabric. Liquid Ammonia Pique Mesh Fabric is treated with liquid ammonia, making the fabric softer and more elastic, and can fit the body curves more well on the body and provide a good sense of sports comfort. For athletes, fit and comfortable equipment can improve flexibility during exercise and reduce sports damage caused by discomfort.

In addition, liquid ammonia mesh cloth also has excellent performance in antibacterial properties. During the intense exercise of athletes, the accumulation of sweat may cause bacteria to grow, which in turn produces a odor. Through liquid ammonia treatment, the antibacterial properties of the fabric are enhanced, which can effectively inhibit the reproduction of bacteria and keep the clothes fresh and clean. This feature is especially suitable for sports equipment worn by athletes for a long time, ensuring that the wearer remains comfortable and hygienic even in high temperatures and humid environments.

For sports equipment manufacturers and suppliers, the application of Liquid Ammonia Pique Mesh Fabric is undoubtedly a strategic innovation. By adopting this high-performance fabric, manufacturers can meet consumers' high demand for the functionality and comfort of sportswear. At the same time, the customization capability of liquid ammonia pickle mesh allows suppliers to provide personalized fabric solutions according to the specific requirements of different brands and sports events, further enhancing market competitiveness.

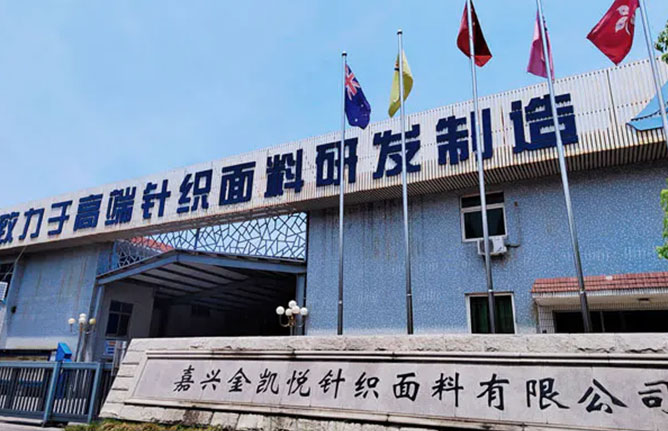

For example, Jiaxing Jinkaiyue Knitted Fabric Co., Ltd., as a manufacturer focusing on high-end knitted fabrics, provides a variety of innovative fabrics including Liquid Ammonia Pique Mesh Fabric by introducing advanced production technology. The company is committed to providing high-quality customized fabrics to customers around the world, and cooperates with many international equipment manufacturers to ensure high quality and excellent performance of products. Jinkaiyue's technical team uses advanced ring knitting machines to provide customers with diverse fabric designs and high-quality sports equipment materials to meet the needs of different markets.

In short, the Liquid Ammonia Pique Mesh Fabric has become a popular choice in sports gear with its excellent breathability, durability, comfort and antibacterial properties. Through liquid ammonia treatment, the various performances of the fabric have been greatly improved, which can meet the high-performance needs of modern sportswear. As the market's requirements for the comfort and functionality of sportswear continue to increase, liquid ammonia pickle mesh will undoubtedly play a greater role in the future production of sports equipment and become a key technology for manufacturers and suppliers to enhance their competitiveness.

Naše proizvodne kapacitete prate snažne istraživačko-razvojne mogućnosti, što nam omogućuje isporuku velikog broja projekata s boljom kvalitetom i kraćim rokovima.

Proizvodne mogućnosti

Snažne proizvodne mogućnosti povećavaju vašu konkurentnost

-

Kako bi osigurao bolju kvalitetu, Jin Hyatt je uložio u najsuvremenije strojeve iz Italije, Njemačke, Švicarske, Japana i Tajvana.

-

Tvrtka se uglavnom bavi raznim materijalima, uključujući dudovu svilu, pamuk s tekućim amonijakom, vunu, kašmir, tkanine za vanjske sportove i razne mješavine vlakana.

-

Tvrtka učinkovito upravlja skladištenjem sirovina i gotovih proizvoda, integrira cijeli proizvodni proces i poboljšava ukupnu učinkovitost.

-

Tvrtka cilja na tržište luksuznih proizvoda s visokokvalitetnim pletivom i posvećuje 20% svoje radne snage istraživanju i razvoju kako bi povećala vrijednost proizvoda i konkurentnost.

中文简体

中文简体